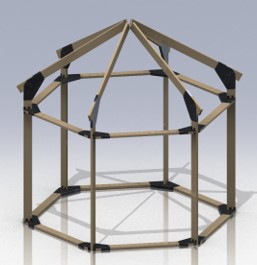

Basic Frame Detail

Shed Project

The combined stiffness of our brackets and the 2x6 lumber is so strong that an upper crossbeam is not necessary for smaller applications like the shed shown, where unlike in conventional methods, it is required. Also, the strength of the 3 brackets combined greatly reduces the moment load on the top beam.

In one of our tests, we took a basic A-frame with beams on 4 sides only, a crossbeam at the bottom only, 9’ tall, and 6’ wide, and we were unable to twist or parallelogram the structure with 4 strong men, one in each corner. This would be unheard of if built with conventional methods.

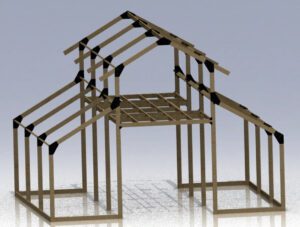

Shed Project

This basic frame structure was built using only two types of brackets in much less time than standard methods.

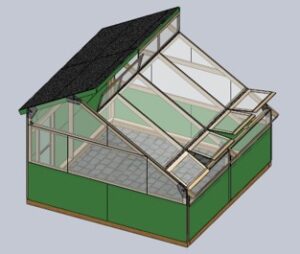

This shed was built in less than a week, costs half as much as a shed kit you buy from a hardware store, and is 10 times stronger. Not to mention, you can customize it any way you want.

Now just imagine this structure scaled up! A single-family home structure built with these brackets could be many times stronger than with current methods. Not only stronger but easier to build and with the potential of using less lumber.

Current Status/Future Plans

Current News

The first round of FEA analysis has been completed with amazing results (as I predicted). The next step is submission to IAPMO-UES for certification. There they will perform their analysis and physical testing. After this has been completed, the brackets will be available to the market to start building homes!

There is also a plan to have demolition load testing done to see how well these brackets really hold up with maximum loads applied to the point of failure. We may even run a side-by-side comparison using a competitor’s product. Stay tuned!

Moving forward, the plan is to create a family of brackets that will accommodate different roof pitches, lumber sizes, different material thicknesses for specific strength requirements, and many more types of brackets optimized for the ease of home construction.

We are also looking into designs for supporting construction efforts with SIPS and CLT lumber manufacturing.